Energy efficiency

We work systematically to improve the energy efficiency of our LNG terminals and biogas plants.

Our aim is to continuously improve energy efficiency in our operations. We have set a 1% energy saving target annually until 2025. Our tools include systematic energy management, audits, and internal campaigns.

We manage and develop our energy efficiency through a certified ISO 50001:2018 energy management system. The energy management system comprehensively covers our supply, production, and delivery of gas products, as well as the processing of biodegradable waste, production of recycled nutrient and fertilizer products, and energy and portfolio management services.

We participate in the voluntary Finnish Energy Efficiency Agreement for Industries under the Energy-Intensive Industry Action Plan. It is an important part of Finland's Energy and Climate Strategy and a primary tool for the promotion of efficient energy use in Finland.

Read about our achievements and energy saving actions from our sustainability report.

We continue to favor the use of 100% renewable electricity in all Gasum operations.

All electricity consumed by Gasum is generated from Nordic hydropower. A significant share of the electricity is utilized in the production of liquefied natural gas (LNG) in Risavika, Norway. The biogas plants use heat energy in their processes. Process heat is produced from non-upgraded biogas, natural gas and landfill gas. Part of the process heat is purchased as district heat.

Circular economy

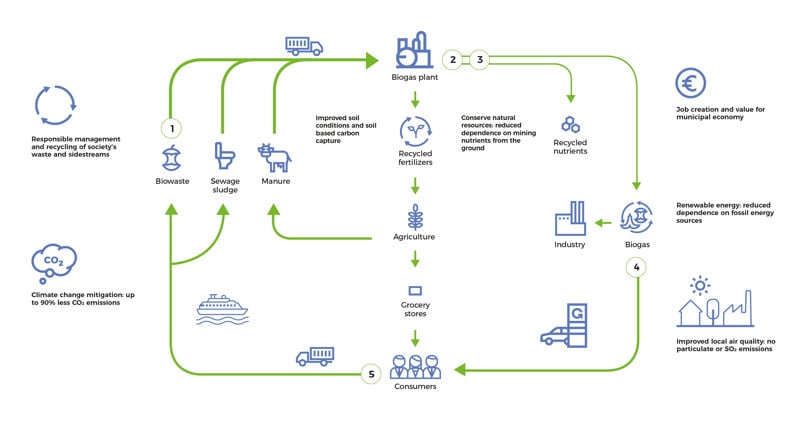

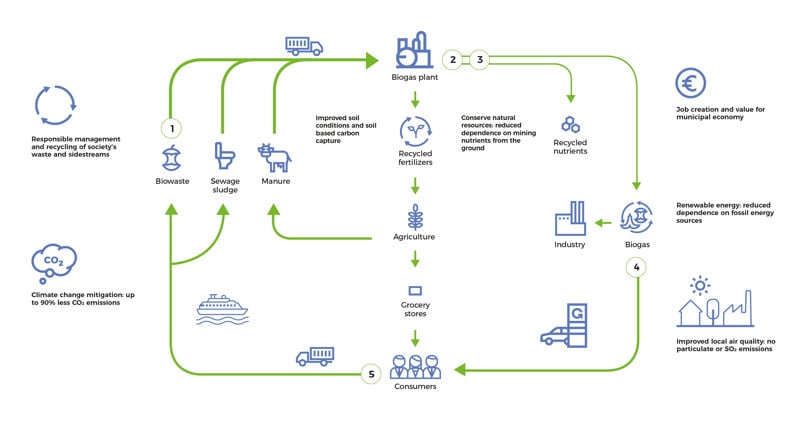

Biogas is a completely renewable fuel produced from agricultural, industrial and household waste and residues. In the biogas production process, the biodegradable feedstocks are converted into energy and recycled nutrients by anaerobic microbes that feed on the biomass. Renewable biogas can be used as a fuel for cars, buses, heavy-duty vehicles and maritime transport, as well as in industry and energy production.

We are a major processor of biodegradable fractions of waste generated in society.

We process biomass from agricultural side streams, crops, manure, inedible food waste from retail outlets, food industry side streams, spoilt batches, and sewage and grease trap sludge. Our waste processing service enables the re-use of biodegradable waste material as energy, thereby reducing the energy lost in processes such as waste combustion or composting.

Besides biogas, our plants produce various recycled nutrients.

Nutrient residues such as nitrogen and phosphorus arising as a by-product in biogas production can be returned to the food chain as fertilizers or refined for industrial purposes to replace mineral and fossil nutrients and fertilizers.

Cleaner energy

Our purpose is cleaner energy. We support our customers in their efforts to reduce greenhouse gas emissions. We seek to increase the availability of renewable and low-carbon energy in road and maritime transport and in industry.

Our aim is clean mobility of people and goods on land and at sea. We offer cleaner and cost-effective energy and raw materials for industry. We also help our customers to master the energy market and provide services and consultancy services throughout the market chain.

Read more

Climate

Climate change mitigation is one of the crucial drivers behind Gasum’s strategy. We are committed to combatting climate change. An efficient way of reducing emissions is to increase the use of renewable energy in road and maritime transport and in industry.

Our goal is to bring 7 terawatt hours (TWh) of renewable gas to the market by 2027. We will achieve the goal though both increasing investment in our own biogas production but also sourcing renewable gas from trusted partners. When we reach this goal, we will have achieved a cumulative carbon dioxide saving of 1.8 million tons for our customers.

In addition, we continue to implement energy efficiency measures and reduce emissions in our own operations.

Our products create a carbon handprint.

The carbon handprint describes and measures the climate benefits, or the emissions avoided by using a product, process or service. The use of fully renewable biogas can help to reduce greenhouse gas emissions over the entire life cycle on average by 90% compared with fossil fuel use. There is potential to reduce emissions even further when manure is used as a feedstock in biogas production, because methane emissions from conventional manure management are avoided.

The raw materials used in biogas production are waste and residue-based feedstocks such as biowaste, wastewater sludge and organic side streams from industry and agriculture. Biogas is produced in our biogas plants in Finland and in Sweden. Read more about biogas production.

In addition to biogas, our plants produce various recycled nutrient products. Recycled nutrient products, such as recycled ammonia solution, can help replace virgin nutrient products. Recycled ammonia solution has 90% lower carbon footprint compared to the industrially produced urea.

Gasum's biogas fulfils EU sustainability criteria.

Gasum’s biogas fulfils the sustainability criteria laid down by the EU Renewable Energy Directive (REDII).

We measure the life cycle impact of our products.

We measure the climate impact of our products with a lifecycle approach. The calculation of the carbon dioxide emission reduction takes into account the entire gas value chain from raw material sourcing to gas production, distribution and use.

The greenhouse gas emissions of extraction of the raw material for biogas is considered to be zero when waste and residues are used in biogas production. In addition, just like with other renewable fuels, the calculated level of use phase emissions from renewable biogas is regarded to be zero. Biogas combustion generates carbon dioxide, but there is no net increase in atmospheric carbon dioxide because the amount of carbon dioxide fixed in the biodegradable feedstock equals the amount released through biogas combustion.

Using gas can result in cleaner urban air.

Use of gas as a fuel can help to reduce local air emissions in urban areas. Cleaner burning than other fossil fuels, the combustion of natural gas, and biogas, produce negligible amounts of sulphur and small particulates, and up to 85% lower levels of nitrogen oxides (NOx), which are precursors to smog.

We help businesses get easier access to renewable electricity.

Gasum is a major actor in the wind power segment and strives to increase procurement of renewable wind power in the Nordic countries. The wind power-based Power Purchase Agreements (PPA) are a favored tool for bringing new renewable energy onto the grid, and they can help companies hedge against power price swings. Partnerships promote our strategy to deliver cleaner energy to our customers in industry.

Environmental management

We make systematic efforts to minimize our environmental impact.

In our daily work, we make systematic efforts to minimize the most significant environmental impacts of our operations: air emissions, energy consumption, odor nuisances, and environmental impacts caused during project construction.

We employ environmentally sound and energy-efficient technologies and ensure efficient maintenance. We continuously improve our operations and comply with the certified environmental (ISO 14001:2015) and energy management system (ISO 50001:2018) requirements as well as a biogas sustainability scheme. We increase our understanding of the life-cycle impact of our products and use this information to improve our performance.

All sites systematically follow up on any deviations and report observations.

All sites systematically follow up on any deviations, pro-actively report observations, conduct safety walks, and compile risk assessments. We use reporting tools in the management and reporting of environment-related actions.

We aim to utilize recycled water in the biogas production process as much as possible.

We see internal recycling of reject water as an economical and environmentally sound solution for operating the biogas plants. Internal recycling improves the plants’ heat balance and reduces the amount of wastewater. Water consumption is also reduced by utilizing site run-off waters in the biogas process, and by optimizing the production processes. The plants are equipped with efficient technologies for water purification and recovery of nutrients and organic carbon. Increased recovery of nutrients helps to lower the environmental load of effluent before discharging it into a wastewater treatment plant. Some of the nutrient rich excess process water is utilized in the forest industry as a nitrogen source for microbes at wastewater treatment plants.

In our LNG supply chain, sea water is used as ballast water in the vessels. After use, the ballast water is released back into the sea unpolluted. Most of our freshwater consumption is as process water in biogas plants and as tap water in offices.

We continue to invest in reducing odor nuisances from our biogas plants.

We strive to reduce the time-to-time nuisances from our biogas plants. We improve odor gas treatment, optimize processes and organize odor observations.

Most of Gasum’s process waste is recycled or recovered.

Sand and packaging materials removed from the raw material stream received for biogas production account for our most significant proportion of solid waste. Most of the waste fractions generated in our operations are recovered or reused.