LNG in industrial processes – the more flexible alternative

Conventional fuels like liquefied petroleum gas (LPG) and oil have been widely used for decades in industrial processes. But as emission limits are tightening all around, liquefied natural gas (LNG) and liquefied biogas (LBG) offer a powerful advantage in sustainability for decades to come.

The energy system is facing a massive transformation as societies move toward carbon neutrality. As industries start to shift away from fossil fuels, they must find cost-effective and reliable ways to power their processes with cleaner, more sustainable energy. Switching to natural gas can reduce emissions in many processes ranging from different industrial applications, heat and steam production, to a variety of different processes. In addition, biogas can bring net emissions to zero.

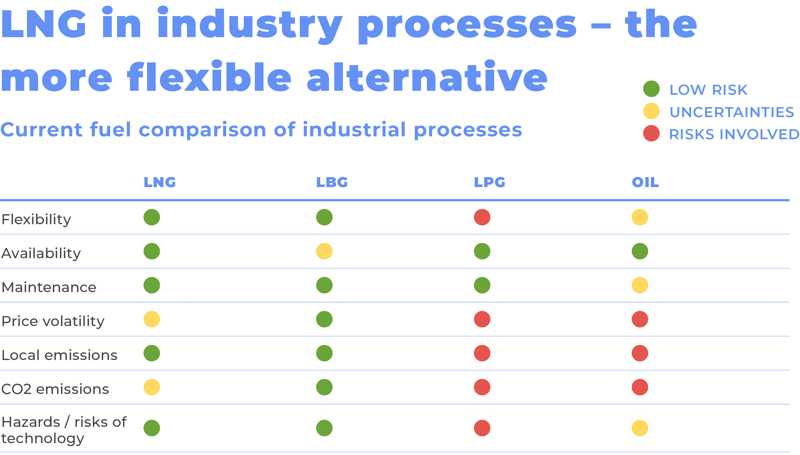

LNG brings the benefits of natural gas to areas outside the gas pipeline network throughout the Nordic countries. But how do LNG and LBG fare against the more conventional fuels like oil or LPG in industrial processes? We compared various features to see how the fuels can compete against each other.

The clear-cut benefits of LNG come from its flexibility and the opportunity to use the same infrastructure for either LBG or blends consisting of LNG and LBG. Blending with LBG lowers emissions even further and thus helps companies in reaching their emission reduction targets more smoothly.

Switching to natural gas or LNG from oil means complete elimination of SOx and particles, and reduction of NOx emissions of up to 85 percent. In addition, LNG reduces CO2 emissions by at least 20 percent compared to conventional fuels, whereas LBG can reduce CO2 emissions by up to 90 percent in a life cycle perspective. Biogas combustion generates carbon dioxide, but there is no net increase in atmospheric carbon dioxide because the amount of carbon dioxide fixed in the biodegradable feedstock equals the amount released through biogas combustion.

Customer evidence also proves that blending in or replacing LNG with LBG is possible without further investments for the customer. This adds to the ease of converting from LPG and oil to natural gas.

Flexibility through blending

The fuels chosen for the comparison are the most prevalent ones in industrial processes. The other existing alternatives are bio-LPG and bio-oils. However, these alternatives are very small in volume compared with LNG.

Conventional fuels like liquified petroleum gas (LPG) and oil have been widely distributed and used for many decades in industrial processes, whereas the benefit of LNG and its infrastructure comes from the possibility to blend in LBG.

“If you switch to LNG, you can start blending in LBG from day one, and you can choose which percentage you want to blend in. The molecule in both is exactly the same,” explains Jerve Trond, Senior Sales Manager, Industry Norway.

When mixing these gases, there are no compatibility challenges. But the benefits do not end there. The methane gas infrastructure is future-proofed, since synthetic gas, power-to-gas and other solutions are entering the market. Thus working as a bridging fuel for several future solutions such as renewable biogas.

All the fuels compared are currently readily available, and the LBG offering is growing every year. By 2027, Gasum will offer 7 TWh of biogas to the Nordic market through our own and partners’ production.

The Nordic infrastructure is very well covered regarding LNG and LBG which, since they are in liquefied form, can be delivered anywhere. As is with oil, LNG’s main logistics is by tanker truck.

All the compared sources of energy are experiencing high volatility in the energy market. But, comparatively, LNG is a future-proofed energy source in the long term. Tough emission reduction targets set by the EU also consequently increase the price of fossil energy alternatives, leaving LBG a price competitive choice.

Safer in various ways

As with any fuels, there are some operational hazards and risks that need to be taken into account when handling them. Hazards and risks could be separated into two categories, local and global. Burning oil or LPG will release more CO2 than burning natural gas.

Concerning local hazards, it is important to note that natural gas is lighter than air. If there is an LNG leakage, it will just evaporate very quickly. LNG can ignite, but being lighter than air, the risk is very much lower than with LPG, for example. If there is an oil leakage, it will turn into an oil spill and can contaminate the soil. As LPG is heavier than air, it will also leak downward to the lowest point and will stay there until something ignites it.

“LNG is methane, which is a powerful greenhouse gas, and it is important to avoid any leakages. However, the local risks regarding LNG are very small,” Jerve adds.

“In addition to being safe to handle, switching to LNG lowers maintenance costs. This is something both we and our customers have seen,” Jerve says.

“Customer evidence proves that maintenance, operations and manufactured products do not suffer when replacing an old energy solution with LNG or LBG,” Jerve concludes.